Manufacturing Technology

Operation

Operating the factory with automatic control.

The factory operates with a fully automated control system in the stages

Weighing the raw materials

Mixing

Adding liquids

Pelleting and cooling

There is no manual intervention in weighing the raw materials or determining their ratios inside the mixer.

all steps are controlled by industrial software (PLC / SCADA) that provides:

High accuracy in weighing each component in kilograms and grams

Consistency in the composition of every production batch, regardless of operating pressure or shift changes

Electronic logging of every process (Traceability), which can be reviewed at any time to link any issue to a specific batch

Result: True consistency in feed quality from one batch to another, with a significant reduction in the likelihood of human error.

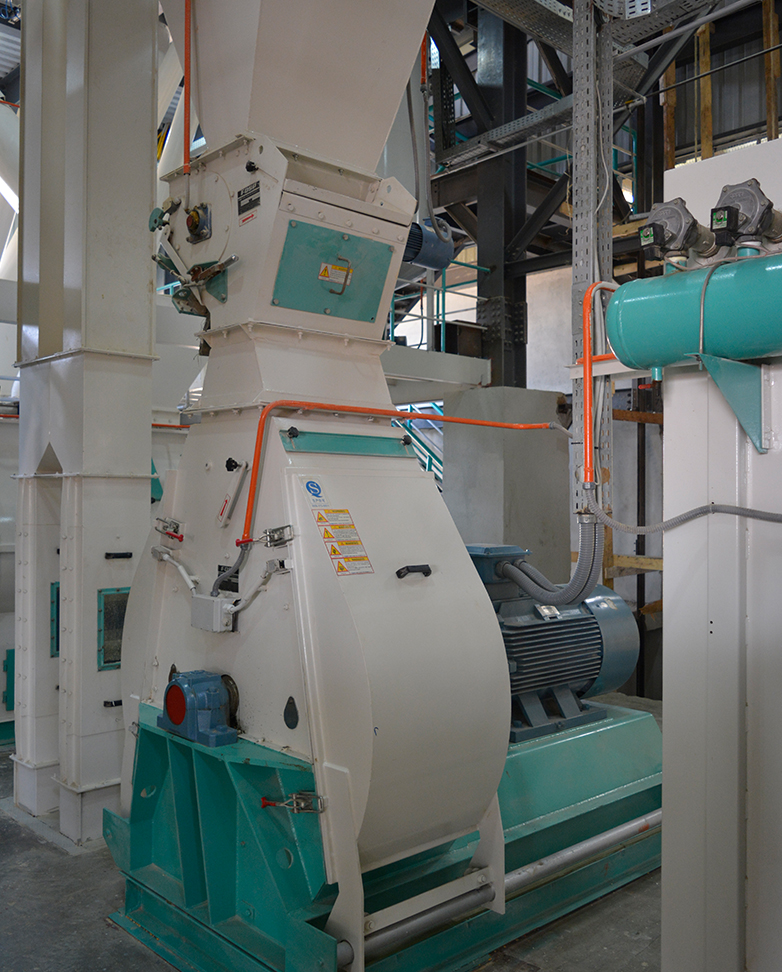

Feed Pellets Presses and Three-Stage Conditioner

Triple Shifter Conditioner Technology

The group uses the latest feed pellet presses in Egypt equipped with a Three-Stage Conditioner (Triple Shifter Conditioner), a thermal conditioning system for pellets that relies on:

Injecting food-grade steam into three consecutive chambers

Increasing the retention time of the feed inside the conditioner

Controlling temperature and humidity gradually rather than abruptly

Samy Ayed Group

Scientific Benefits

Thermal sterilization of the feed

- The conditioning temperatures plus sufficient exposure time help reduce the microbial load in the feed, especially harmful bacteria.

- This increases feed safety and reduces the transmission of microbes through the feed.

Starch Gelatinization

- Heat and steam break down the crystalline structure of cereal starch and convert it into a more digestible gelatinized form.

- This improves the bird’s utilization of metabolizable energy (ME) in corn and other grains, and helps enhance the feed conversion ratio under proper management.

Improving Nutrient Availability

- Gradual thermal conditioning facilitates the breakdown of bonds between starch, protein, and fiber, increasing the bioavailability of protein and amino acids

- The efficiency of feed additives (enzymes, yeasts, probiotics, etc.) is improved

Feed Pellet Quality

- Proper conditioning before pelleting increases pellet durability (Pellet Durability Index) and reduces the amount of fines

- This reduces losses in feeders and ensures uniform feed consumption in poultry houses or livestock pens.

Today, the group serves all poultry and livestock farmers across Egypt. Contact Us

Laboratory

Quality Control System.

Wet Chemistry Laboratory

No raw material is allowed into the storage unless it has passed through the quality laboratory.

The raw materials are analyzed to ensure:

Crude protein content

Fat and fiber content

Moisture and free water content

Mineral content (Calcium – Phosphorus – Sodium, etc.)

Verification of compliance with the required specifications for each formulation

Wet chemistry methods are used, which are the globally recognized reference methods for analyzing feed components

NIR Device – Near Infrared Spectroscopy

Equipped with the latest calibration software and linked to the chemical lab results to ensure accuracy

The device allows for:

Rapid testing of dozens of samples daily within a few minutes

Instant measurement of protein, fat, fiber, moisture, etc.

Monitoring the consistency of raw material quality across suppliers and shipments.

Combining NIR and wet chemistry provides a balance between speed and accuracy, making the decision to accept or reject raw materials a scientifically documented one.

Testing every batch of the final product

After pelleting and cooling, samples are taken from each production batch and tested to ensure:

Pellet shape, uniformity, and freedom from visible defects

Hardness and resistance to crumbling during transportation and handling.

Moisture and free water content to ensure no fungal growth or spoilage during storage.

Nutritional components of the feed (protein – fat – fiber – minerals, etc.) according to the specifications indicated on the product

With this system, the feed transforms from a mere ‘raw material mix’ into a scientifically monitored product at every step, from the moment the raw material arrives until the bag leaves the facility.

Team

Quality and Research & Development Team.

An independent team consisting of

Quality specialists

Chemists

Veterinarians and nutrition engineers.

The team works on:

Setting standard specifications for raw materials and products and reviewing them periodically.

Conducting field trials on farms to measure actual performance and adjust formulations

Studying the latest feed additives and practically measuring their effect on

• Growth

• Feed conversion ratio

• Mortality rates

• Gut health and immunity

• Meat, egg, or milk quality

Today, the group serves all poultry and livestock farmers across Egypt. Contact Us